Should durability be a factor in determining the labels for your products? The answer to this question depends on the product you have for sale in the market.

For example, if you sell a water bottle, you would only like the label to be good enough to sustain until the expiry date you printed on the bottle. After the expiry date, the water bottle will no longer be used. So, what’s the purpose of having a durable label?

Now, the question is when to choose the durable label for your product and how you can ensure its durability. That’s what we’ll address in detail in this article.

Durable goods

Durable goods are the ones that often work for the long term. They are different from consumable goods, with a specific expiry date after which you cannot consume (food, beverage, cannabis, health products) those products. Durable goods mainly include industrial products made from hard materials like plastic, composite and metal.

The labels used on durable goods can be referred to as durable labels.

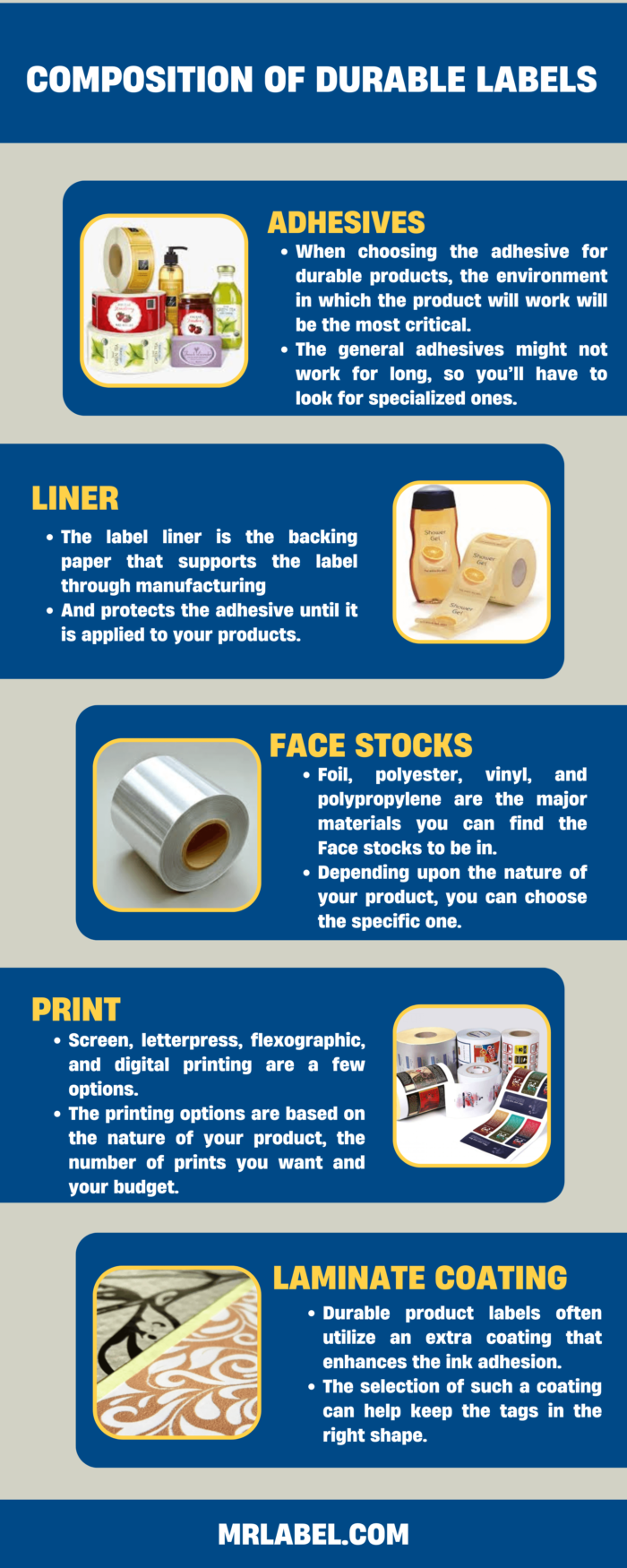

Composition of a durable label

Durable goods might have the same components as standard labels, but their strength and quality might differ. Let’s have a look at some of the critical aspects that make a label a durable one:

Adhesives

When choosing the adhesive for durable products, the environment in which the product will work will be the most critical. The general adhesives might not work for long, so you’ll have to look for specialized ones.

Face stocks

Foil, polyester, vinyl, and polypropylene are the major materials you can find the Face stocks to be in. Depending upon the nature of your product, you can choose the specific one. For consumable products, paper face stocks are prominently considered. But you can use plastic films like polyester (PET), polypropylene (PP), and other synthetics for longer usage.

Screen, letterpress, flexographic, and digital printing are a few options. Depending on the nature of the products, the number of prints required and the budget, you can select from any of these printing options available.

Laminate Coating

Durable product labels often utilize an extra coating that enhances the ink adhesion. The selection of such a coating can help keep the tags in the right shape.

How to test if the durable labeling will sustain?

You might include all these elements in a durable label, but how would you know if these labels will stay on your product for as long as the product’s life? To check this aspect of the durable labels, you can perform the following checks:

Tensile strength

By testing the tensile strength of your label, you’ll be applying pounds of force over it and checking if the label is resistant to ripping and tearing.

Peel adhesion

Special machines can be used to perform this check. The machines use force at 90 degrees from various angles to identify the exact force required for the removal.

Chemical resistance

Depending on the product you sell, you might want to use the chemical resistance test, in which the labels are tested against typical cleaning agents like Windex, 409, and isopropyl alcohol.

Apart from these tests, you might want to perform adhesion and real-life application testing to ensure that your labels are perfect for durable products.

Summing up

Not all the products would require durable labeling, but those with durable nature will need one. You can utilize efficient raw materials and printing techniques for this purpose. Besides, there is a range of tests that you can perform to ensure the durability of the labels.

To get custom labels for your durable products, you can contact us. Talk to our expert and get an obligation-free quote for your label printing needs in Chicago.