Heat transfer and silk printing are the two most-used techniques to print fabrics for shirts, different garments, and home textiles. If you are considering printing for any fabric, the first introduction will be to these two techniques.

However, how will you decide which one is better?

What’s the difference between silk screen printing and heat transfer? Here is all you need to know so that the outcome of your project is better than expected.

Printed fabrics are a new thing, and there are many reasons why this technique has become popular. Simultaneously, heat transfer has its perks. So here is a detailed introduction to both techniques so you can decide which one is for you.

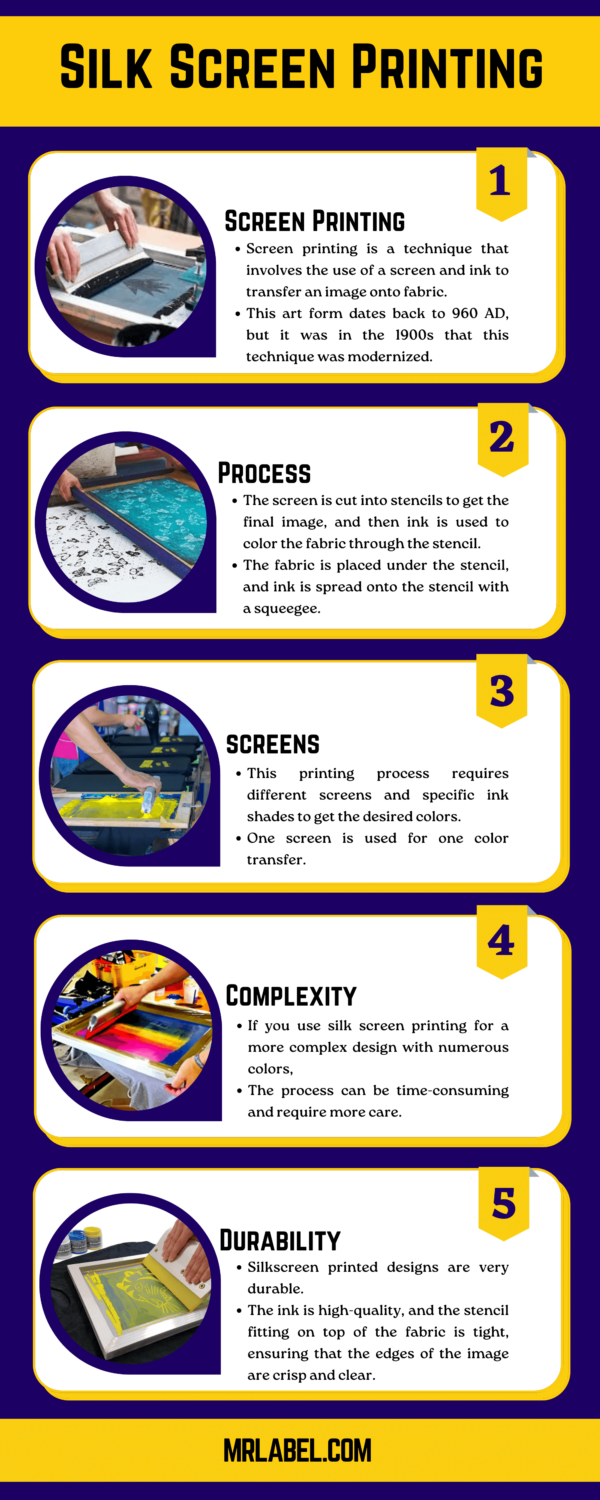

Silk Screen Printing

Screen printing is a technique that involves the use of a screen and ink to transfer an image onto fabric. This art form dates back to 960 AD, but it was in the 1900s that this technique was modernized.

The screen is cut into stencils to get the final image, and then ink is used to color the fabric through the stencil. The fabric is placed under the stencil, and ink is spread onto the stencil with a squeegee.

One screen is used for one color transfer. Suppose you are creating a flower image; one screen will be for the lighter parts of the flower, while another will be placed afterward to create an outline or the darker edges of the flower. A third screen will be used for the green stems.

This printing process requires different screens and specific ink shades to get the desired colors. The design team has to check the final look to ensure the fabric is kept from being moved while printing, which can spoil the design.

If you use silk screen printing for a more complex design with numerous colors, the process can be time-consuming and require more care. Screen printing lasts a long time, and that is one of the most significant advantages.

The ink is high-quality, and the stencil fitting on top of the fabric is tight, ensuring that the edges of the image are crisp and clear. This printing can endure more than 60 washes before you see the colors dull down. However, the ink used for screen printing is quite thick, and if you wash it inside out, the colors can stay on for an extended period.

How Do Screen Printers Work?

Screen printers and hand printing can be equally effective for screen printing quality. However, printers are faster, although they work through the same technique.

Users must create a design and select the ink and mesh count for it. The emulsion is exposed, and you will have to make the stencil. Prepare the printer and apply the design so the printer begins coloring parts of the image according to the colors needed. Once the printing is complete, the fabric has to dry.

Pros and Cons of Silk Screen Printing

For further understanding, here are some pros and cons of this printing technique:

Pros

- Cost-effective for larger quantities

- The fabric does not become stiff and pasty

- Designs are durable

- Allows darker colors to be used without rough application.

Cons

- Intricate designs can be challenging for this printing technique

- Process can be time-consuming if the image requires more colors

- Not suitable for a smaller quantity

- Photo replication is a problem for this technique

- Uses a lot of chemicals.

What is Heat Transfer Printing?

Heat transfer printing is a newer technique when compared to silk screen printing. In the past decades, this technique has become a hot favorite for fabric printing.

This method involves printing of an image onto fabric with heat and pressure. There are two types of heat transfers: vinyl and digital printing. Vinyl heat transfer processes use a machine to cut out designs of colored vinyl, which are then transferred to the fabric using heat. This method is effective for printing a wide range of fabric types.

Active sportswear, jerseys and t-shirts are some of the most typical items on which you see the heat transfer technique of printing.

A heat transfer printer works like a home printer as a graphic image is designed on the computer, and then the fabric is placed in the printer. As the command is given, the printer will transfer vinyl ink, which is solvent and adheres to the fabric instantly.

Due to the vinyl ink, the image remains vibrant and new for a long. Moreover, the printing will require a drying period to ensure that the image is fully attached and can be touched. The high resolution image is loved by all and that is why this printing technique became very popular during recent years.

Heat transfers are a great way to print if you have smaller prints, but the time taken for the image to dry will still be significant. If you move the fabric too soon, the printed image will get smudged, and the surrounding fabric will also get spoiled.

Pros and Cons of Heat Transfer

Here are some pros and cons of heat transfer

Pros

- Cost-effective for smaller orders

- Easy to print and no repetitive steps

- Affordable setup and printer

- Allows you to customize colors

Cons

- Not suitable for dark fabrics

- Design can spoil in heat

- Design is not long-lasting like screen printing

- Colors are not bright.

Which Printing Technique Is Better?

The printing method that is most suitable for you is the one that suits your fabric and printing needs. Are you printing for a high volume of garments? Will you require smaller prints or larger prints? Will you need vibrant colors?

If you are looking for intricate designs with many colors, heat transfer may be better. However, if you are using designs that are big in size and do not have a lot of colors, silk screen printing is a better option.

Heat transfer is a more straightforward process and does not have multiple steps so if you have less time and you want to print a smaller quantity, you should select this process. Nevertheless, silk screen printing is an excellent choice for large prints and higher quantities of fabrics.

If you need help with your product labels, M&R Label can help you. Contact us for more details.