It requires a few seconds for customers to get impressed with a label. If the consumer gets captivated by a label, there is a high chance that they will become loyal customers in the long run.

With all kinds of marketing techniques, the impression has to be instantaneous, otherwise the business owners can notice stagnant sales figures.

Without capturing consumer attention, the chances of making a sale, regardless of how great the product is, are slim.

There is plenty of research that indicates that the appeal of packaging can trigger impulsive buying, even among consumers who have no intention of purchasing anything. In physical stores, packaging and labels often play a crucial role in influencing decisions, especially when products are displayed side by side, all competing for attention.

How can a product label designer increase the likelihood of capturing and retaining consumer attention? Utilizing print finishes on labels can significantly enhance or detract from a product’s appeal.

Label design is a blend of art, and psychology within the parameters of law and regulations. While all three aspects require careful consideration, capturing attention remains the most crucial. At M&R Labels, we offer a wide array of choices that will give you the best results.

10 Print Finishes for Labels that Capture Attention

There are numerous kinds of label finishes that will prove beneficial for a brand. Labels primarily come in two forms: digital and flexographic, which influence the available finishes.

There are numerous kinds of label finishes that will prove beneficial for a brand. Labels primarily come in two forms: digital and flexographic, which influence the available finishes.

Digital labels are produced electronically, without the need for printing plates. The digital image is printed directly from the computer onto rolls of paper, film, or foil using inkjet or toner. Flexographic labels, or flexo, are printed with flexible rubber or photopolymer plates. Due to the cost of plates, flexo is typically used for high-volume label production.

With this context in mind, here are ten creative ways to enhance product label designs and better capture consumer attention. A reference chart is included to assist in planning your next label printing and finishing job.

-

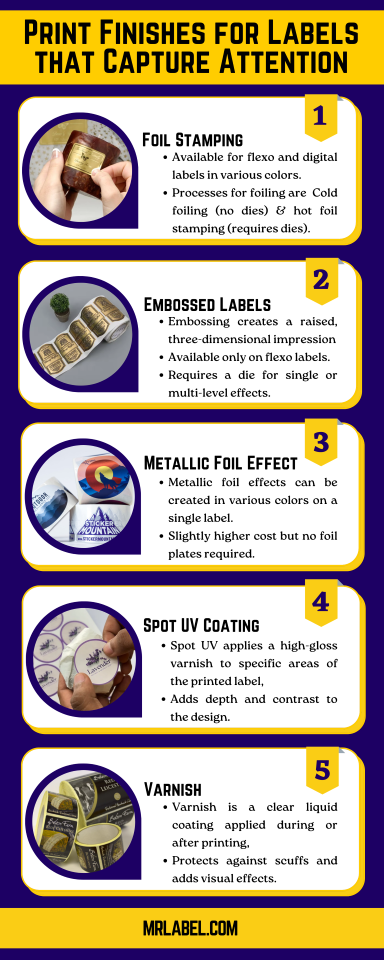

Foil Stamping

Foil stamping can be applied to both flexo and digital labels. Foils come in a wide range of colors, including various shades of gold, silver, metallics, pigments, holographic images, and clear foil. There are two processes for foiling: cold foiling, which does not require dies, and hot foil stamping, which does.

-

Embossed Labels

Embossing creates a raised, three-dimensional impression on the label and is available only on flexo labels. This process requires a die and can produce single-level or multi-level impressions, creating striking 3D effects.

-

Raised Foil in Gold or Silver

Raised digital foil is thicker than conventional foil and can be felt when touched. It delivers a similar visual and sensory effect as embossing, but without the need for embossing dies, making it a more affordable option available only on digital labels.

-

Metallic Foil Effects

Metallic foil effects can be created in various colors, often allowing for multiple colors on a single label. Since no foil plates are needed, printing costs are only slightly higher than standard full-color labels.

-

Spot UV Coating

Spot UV applies a high-gloss varnish to specific areas of the printed label, dramatically highlighting certain colors, images, or design features. Creative high-contrast designs can add depth and eye-catching appeal to any label.

-

Raised Spot Gloss UV

This advanced version of regular spot UV coating provides a depth that is both visible and tactile, similar to embossing. It is exclusive to digital labels and is cost-effective due to the absence of dies or expensive setups.

-

Overall UV Coating

Overall UV coating applies a high-gloss varnish to the entire label, creating a wet-look finish that enhances details and images while providing additional protection and smudge resistance.

-

Lamination – Dull or Gloss

Lamination involves applying a thin layer of clear film to the printed label using heat and pressure. Available in dull or gloss finishes, lamination offers maximum protection for labels.

-

Soft Touch Lamination

Soft touch lamination differs from regular lamination by providing a velvety texture. This luxurious finish is ideal for premium products and designs, adding an appealing sensory element.

-

Varnish

Varnish is a clear liquid coating applied during or after printing, available in gloss or dull finishes. It can be used overall or in specific spots, allowing for striking visual effects while also protecting against scuffs and smudges.

Getting the Most from Label Finishes

The ten finishes listed can be creatively combined to produce visually stunning effects that make products stand out, both on shelves and in e-commerce. Whichever finish you select must be compliant with a few factors such as the nature of your product and the kind of competition that you want to beat.

If business owners can focus on marketing techniques while ensuring the quality of products and label requirements according to the rules of authoritative bodies, these finishes can yield the best results and your sales figures will keep rising.

If you’re interested in learning more about our label services and would like us to provide you with a FREE quote, trust the experts at M&R Label to help you!

Call Us at (708) 534-6621 or Request a Quote!