Knowledge of different kinds of printing can be a good way to understand the cost and time required for label printing. There are two primary kinds of label printing techniques, and each of them can be advantageous in unique ways.

If you want to know which kind of printing is good for your business, find out what each of these methods offers. Flexographic label printing and digital label printing are explained in detail for you to decide what you would need.

Flexographic Label Printing

Flexographic label printing is the conventional method, which is similar to the printing press technique. The text and design of the label are made on a plate and then ink is applied to the raised parts of the plate, and it is used like a stamp or press.

This method is efficient for the high-volume production of labels, and it requires a press machine, which prints the required material by pressing the plate on it. This method is used in numerous industries today. However, there are some pros and cons that you should know before adopting this method of printing.

Pros

• Excellent for high-volume label printing.

• Good quality printing for years

• Good quality finishing with varnish and screens

• Best option for long-term campaigns and label production

Cons

• Requires knowledge and manual skill

• An operator has to use the machine, and there can be many levers and knobs to handle

• Is costlier than digital printing

Flexographic is a better option for businesses that require high-volume production like printed papers, letterhead notepads, merchandise printing for their office, and other such materials that are produced in bulk.

Another efficient use of flexo printing is that it gets the color selection done in the best way. If you have specific color requirements, the flexo printing method is useful. However, the time and cost for this kind of printing are high, and if you have a new business set-up or you are not ready to invest in expensive label printing, there can be other alternatives for you.

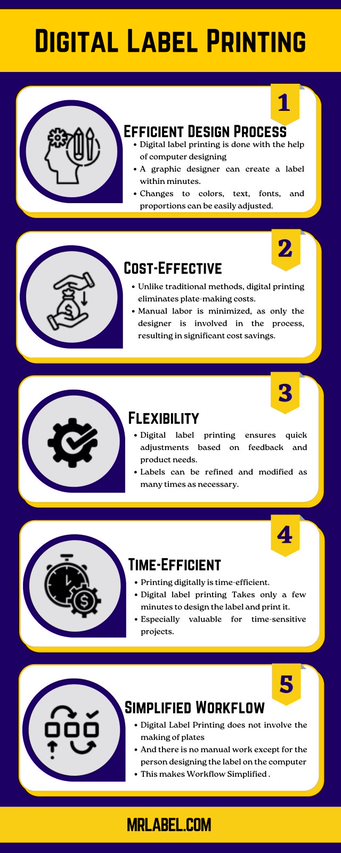

Digital Label Printing

Digital label printing is done with the help of computer designing, and a professional graphic designer can have a label ready within minutes. You can change the colors, the text, and even the font sizes and label proportions to fit the product packaging perfectly.

Digital label printing is done with the help of computer designing, and a professional graphic designer can have a label ready within minutes. You can change the colors, the text, and even the font sizes and label proportions to fit the product packaging perfectly.

Since the design does not involve the making of plates and there is no manual work except for the person designing the label on the computer, the cost of digital designing is significantly less.

Moreover, this printing method gives you the flexibility of creating new labels in a short time. Here are some pros and cons of digital label printing for you.

Pros

• No need for making plates before you test the label

• Only one person can design and print the label; you do not need a lot of labor

• The digital label can be altered as many times as needed.

• Takes only a few minutes to design the label and print it

Cons

• Maybe it is too economical for many business owners to ever consider flexo printing!

Digital label printing is a good choice for many reasons, the foremost of them being cost-effectiveness. If you need different labels for short run or if you have many different colors to present, digital label printing is for you.

However, despite all the amazing benefits of digital printing, flexo will remain the backbone of the industry, and the reason for that is its reliability and our trust in human work. Many people still feel more comfortable with flexo printing because there is a person turning knobs, and moving levers to print labels on a press-like machine.

The colors are selected by workers, and therefore, the human touch makes this method a more comfortable choice.

Which Printing Style Is Better?

We cannot put a finger on any of the printing techniques and say that, yes, this one is better for you. As mentioned earlier, a lot of business owners are comfortable with Flexo only because they feel better if there is human participation.

However, the majority of people prefer to advance as technology advances, and they prefer digital printing due to its low cost and flexibility of running short campaigns at a reasonable cost. Nevertheless, your business and personal choice will play a role in deciding which printing technique is good for you.

If you have a new business or a small enterprise, you may consider digital printing for labels because it is economical. Moreover, well established businesses can spend money on machines and labor needed for flexo printing, but new business owners might not want to spend a lot of money.

Some Common Questions

• Will Flexographic label printing allow us to change the specifications on each food container?

With flexo printing, you will have to create labels for each size of the container you offer. For example, if you need a label for a carton of milk in one liter and a half liter, the labels for each will be made on plates separately and the weight will be mentioned. You will use these two labels where needed.

• Is digital printing difficult?

Digital printing is easy and it requires only a professional to work on a label using computer software. There are no press machines, or labor involved. Moreover, the label is saved as a soft copy that can be edited later to change the specifications.

Last Words

Flexographic label printing vs. Digital label printing can be a long debate, which results in economic and personal preferences for business owners. There are numerous pros and cons of each printing technique and we cannot determine which one is better for you. However, if you go through the details of each, you can decide which one is best for your business.

M&R Labels can offer you the best product labels in town. We are a Chicago-based label printing business that specializes in multiple industries. Contact us now to learn more!