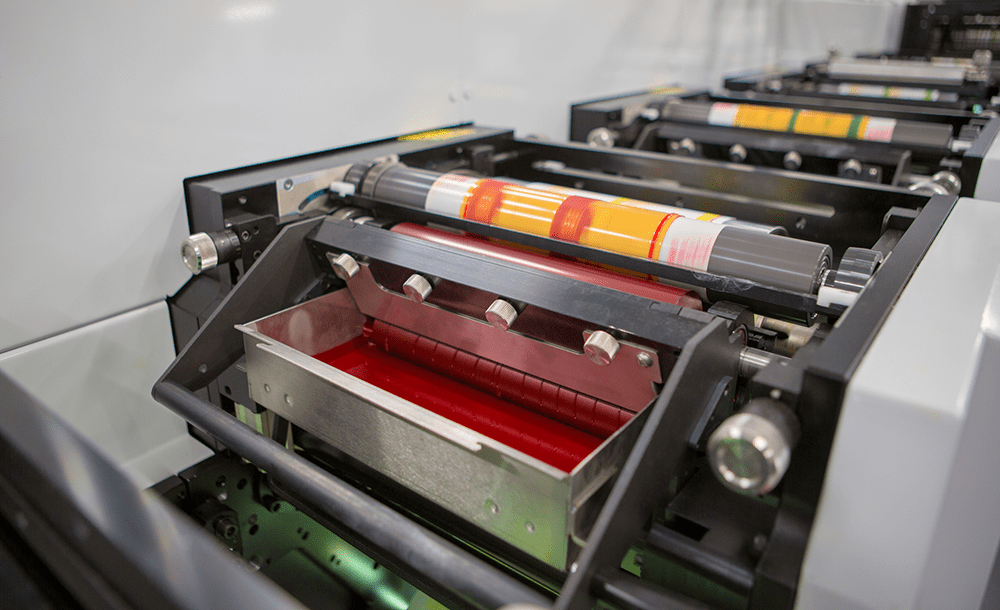

Flexographic Label Printing

Flexographic Label Printing (commonly referred to as flexo) label printing is a super fast and efficient method. It’s typically used for high-volume applications. This form of printing utilizes a flexible relief plate. A flexible printing plate is used to transfer ink to printable substrates in a high-speed rotary process.

Flexo can be used for printing on almost any type of substrate, including plastic, metallic films, foils, boards, cellophane, and, in most of our uses, paper. You’ll likely see flexographic product labels on any type of product, making it a great solution for any company. A few examples of products printed on flexo presses include adhesive and shrink-sleeve labels (as you see on bottles), cartons, bags, gift wrap, labels, envelopes, and so much more!

Since 1989, M&R Label has been using flexo presses to print millions of labels for many applications across industries. Fun fact: these presses can achieve speeds of 500 to 2000 feet per minute!

Flexographic label printing has several advantages:

- Ideally suited for longer runs as press speeds are typically between 180 and 320 feet per minute, resulting in a lower price per label for you.

- Ability to produce solid colors on many different substrates.

- Lower cost of consumables.

- Flexographic printing equipment can be eco-friendly. For example, the use of water-based inks minimizes the environmental impact and reduces the level of toxins that are released into the air.

Read: Digital Label Printing

Work With M&R Label

Let the label specialists at M&R Label handle your custom label printing needs!