When choosing the labels for your product, you must consider multiple factors. Some of these factors include choosing the right material, designing the label, and their readability.

In this article, we’ll talk about the readability of product label printing in Chicago and the few techniques that can help improve the tracking of the product.

Readability and tracking of the product labels

You might be wondering why you need your labels to be readable and traceable. Well, the simple answer to this question is that readable labels can help in tracking every individual unit from manufacturing to the point of sale.

It doesn’t only help to track the sales data but also provides help in identifying its location, price, and overall inventory status.

How to make the product labels readable?

Barcoding and RFID (Radio frequency identification) are the two techniques integrated with the product labels to provide product readability and traceability.

These techniques have a unique identification number or code associated with an individual product that ensures that every unit is separately recorded.

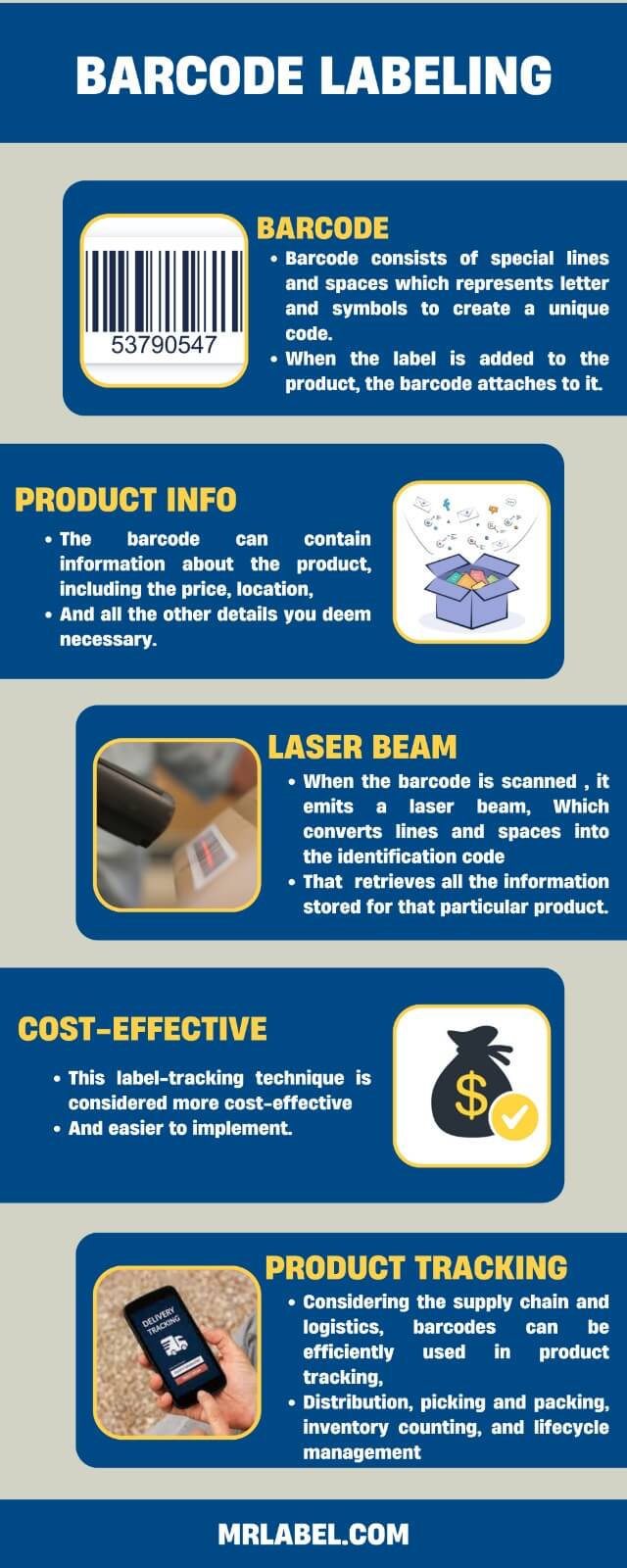

Barcode labeling

In this technique, a barcode is added to the label. It consists of special lines and spaces which represents letter and symbols to create a unique code.

Each label has a unique barcode. When the label is added to the product, the barcode attaches to it.

The barcode can contain information about the product, including the price, location, and all the other details you deem necessary. When the barcode is scanned using the barcode scanner, it emits a laser beam, which converts lines and spaces into the identification code that retrieves all the information stored for that particular product.

This label-tracking technique is considered more cost-effective and easier to implement. Considering the supply chain and logistics, barcodes can be efficiently used in product tracking, intake and distribution, picking and packing, inventory counting, and lifecycle management.

RFID (Radio Frequency Identification) labeling

RFID tag or label contains an electronic chip. The technology works with wireless communication technology that uses a scanning antenna, a transceiver, and a transponder.

When such a label is attached to the product, it emits radio signals. An RFID reader is used to receive these radio signals and retrieves the information associated with them.

RFID technique has advanced tracking and monitoring features, which are effective for complex needs. However, it costs higher than the barcode technology and might create problems in the identification of a single product in case of bulk testing.

The RFID technology works best in asset tracking, product tracking, warehouse management, and inventory tracking.

It is often used in healthcare, automotive, and supply chain management industries.

Summing up

Both barcoding and RFID techniques are helpful in tracking inventory via tags or labels. Although both techniques are effective, you can use them specifically depending on your requirements and circumstances.

If you want to know more about these product labeling techniques, you can contact us now. M&R Labels is a custom-label printing company that helps businesses across different industries.